Pressform: 33, 35, 45

Pressform Professional: 45, 50

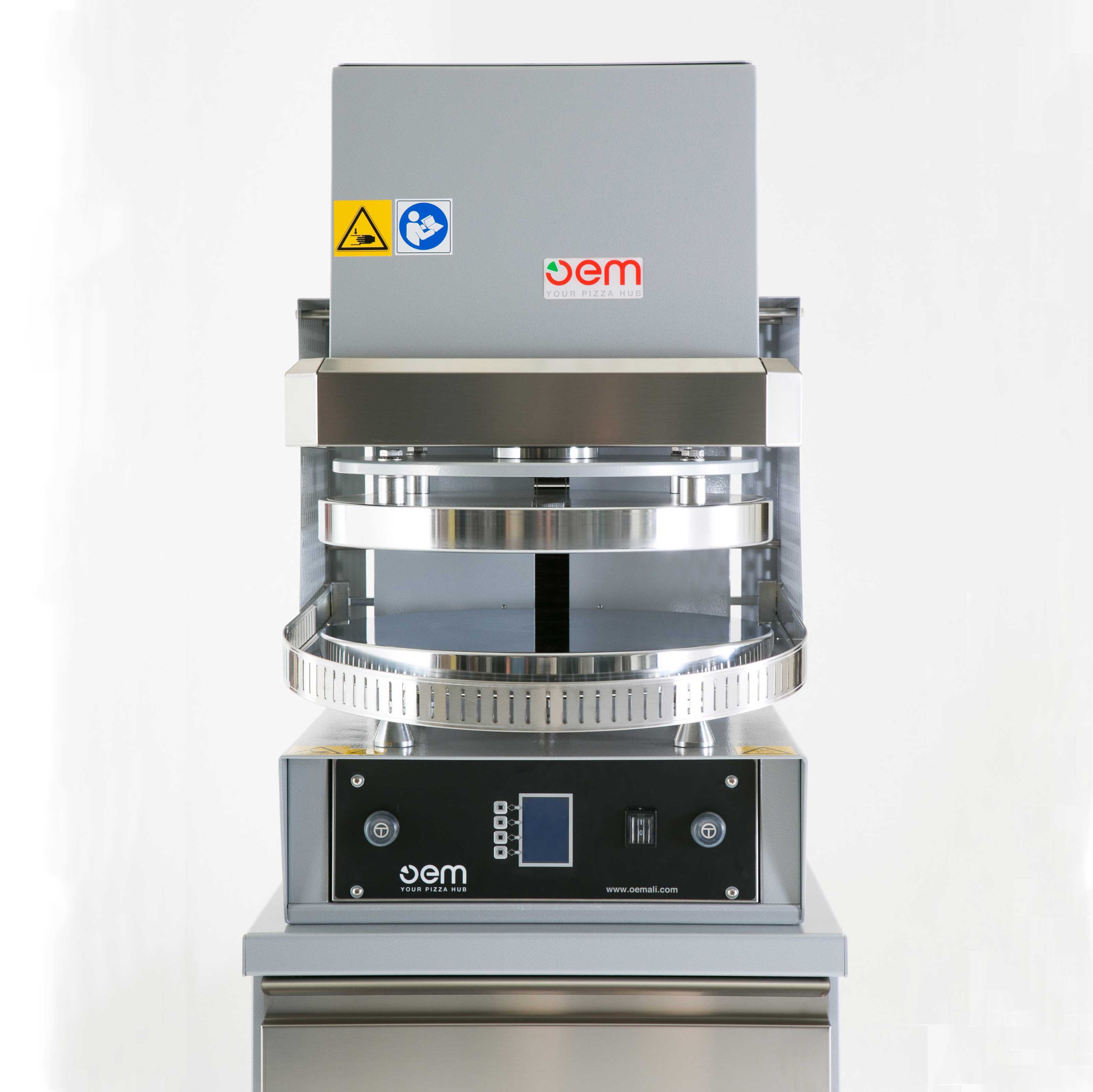

Rolling a pizza base by hand requires considerable time, effort and a great deal of experience.

The manual work involved in rolling out pizza bases requires a lot of time, effort and experience. Oem simplifies this stage with its ‘hot’pressform, which shape pizza dough quickly and evenly. Less effort for you and a reliable, ever-present ally for preparing your bases.

HOW CAN THEY HELP YOU IN YOUR WORK?

High Speed

One base every 3 seconds

Great Productivity Capacity

250 bases for pizzas each hour (including “dead time”).

Uniform Results

The bases are standard size and high quality. You can stack them before adding the filling without worrying about them sticking together.

Discs of various diameters and thicknesses

You can create discs of varying diameters (from 33 to 50 cm). With the knob adjustment, you can also decide the thickness of the dough.

Pizza with or without raised edge

Il piatto superiore svasato all’esterno consente di formare il bordo della tua pizza; il piatto completamente liscio crea un disco totalmente piatto.

Faster baking times

Hot presses do not prebake the dough, however they do remove moisture so baking in the oven is much quicker.

Less effort, higher precision

Powerful and easy to use, hot pressforms take the hard work out of rolling out dough, leaving you more time to focus on filling and baking. The balance between heat, pressure and pressing time, combined with perfectly risen and matured dough, determines the quality of the final product.

CHOOSE THE ‘TAILOR-MADE’ MODEL FOR YOUR PIZZA

Pressform Range

It is a safe and reliable machine, having successfully passed 350,000 test cycles in the laboratory.

- Pressform 33 for discs with a diameter of 33 cm

- Pressform 35 for discs with a diameter of 35 cm

- Pressform 45 for discs with a diameter of 45 cm

Pressform Professional Range

The Pressform Professional range delivers an even greater high-tech performance, using a recirculating ball bearing for smooth, powerful operation and thicker plates that offer improved heat retention. This can rightly be considered a heavy-duty appliance having actually completed 1,100,000 test cycles. A true record!

- Pressform professional 45 for discs with a diameter of 45 cm

- Pressform professional 50 for discs with a diameter of 50 cm

YOUR BASE IN 4 STEPS

- Specify the characteristics of your base using the timer and thickness gauge.

- Place the dough ball in the middle of the plate.

- Switch on the machine making sure you follow the safety procedures for the model in use. The plexiglass protection is lowered and the plates flatten the ball, creating a disc of the required diameter and thickness.

- After lifting the plexiglass, the plates separate and you can remove the disc. You can now prepare the topping or stack in piles.

)

Get more details

Please provide your name and email or phone number, along with the reason for your request. We will get back to you as soon as possible.

Contact us for more information

A team of experts will be at your complete disposal and will answer your every need